ETP- Copper – Electrolytic Tough Pitch Copper

What is ETP copper rod?

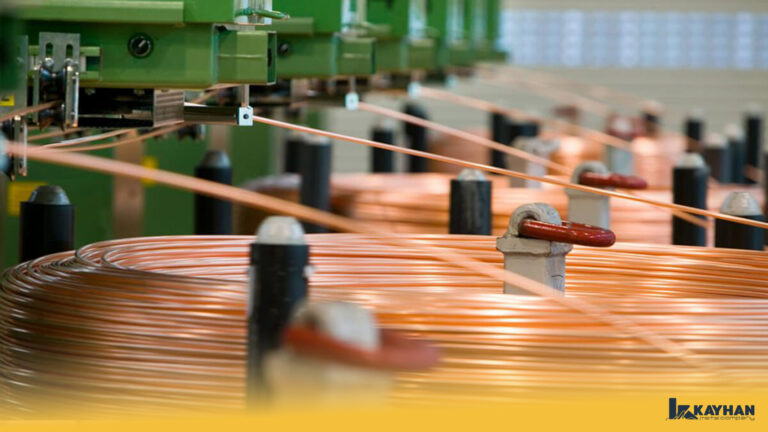

etp is an abbreviation for electrolytic tough-pitch copper, which is a vital element in the world of metals and various industries. electrolytic Tough Pitch Copper, which has long been one of the different types of copper, is used in the production of hard rods.etp copper rod wire in kayhanmetal company is one of the materials that is used in metallurgy and industrial applications due to its versatility conductivity and reliability.in this article, we delve into the significance of ETP copper rods in modern industry, exploring their properties, applications, and impact

ETP copper rod specification

| SPECIFICATIONS | RESULTS |

|---|---|

| Standards | According to ASTM B49 |

| Types | Cu-ETP Copper wire |

| CU | 99.99% |

| Oxygen | 100 to 650 PPM |

| Diameter | 7.9 to 8.1 mm |

| Weight Resisitivy at 20 °C | ≤ 0.15328 Ω·g/m² |

| Surface Oxide Film | ≤ 750 Å |

| Elongation | 40 to 43 |

| Electrical Conductivity at 20 °C | ≥ 100 % IACS |

Due to the many advantages of copper rod, market fluctuations and various parameters that exist for copper products, we suggest to contact our consultants to know the latest and most updated price of ETP Copper Rod.

PACKAGING DIMENSIONS ETP COPPER ROD

The packaging of ETP copper rods is important to ensure that the rods are protected during shipping and handling.Different types of materials are used for packing etp copper rods. Some common materials used are

- wooden box

- essteel frames

- plastic packaging

Wooden boxes are usually used to package ETP copper rods. They are sturdy and provide good protection against damage during shipping. Steel frames are also used especially for larger bars. They are strong and can withstand the weight of heavy rods. Plastic packaging is used for small and light bars.

ETP copper rod applications in industry

ETP copper has long been revered for its exceptional electrical and thermal conductivity properties, making it indispensable in various industries, including

- electronics

- telecommunications

- power generation

- renewable energy

ETP copper rods have different uses. One of the main and key uses of copper etp is to turn into rods of different diameters and lengths, including 8 mm copper rod. ETP copper rods are manufactured through a precise process that involves electrolytic refining of copper to achieve high purity levels.

In the field of electricity, they are used as a column for power transmission, the core of electrical cables and wiring systems. Their high conductivity ensures minimal energy loss during transmission, making them ideal for remote power distribution networks. also, copper rods are used in the production of connectors and switchboards. another significant and practical advancement of ETP copper rods is its continuous casting techniques, which enable the production of rods with improved surface and better dimensional accuracy. in addition, ETP copper rods have alloy elements such as silver and phosphorus for strength, corrosion resistance and machinability.